How to Distinguish Between Coated Woven PP Bags and Laminated Woven PP Bags

1. Similarities

The surface of both types of bags is coated with an adhesive film layer on woven PP fabric. Therefore, the bags can be cut with scissors without fraying, resulting in clean-cut edges. The full-body film layer helps the bags effectively resist water penetration and moisture. However, after packaging, there might be some residual moisture inside the bags.

2. Differences

| Coated Woven PP Bags | Laminated Woven PP Bags | |

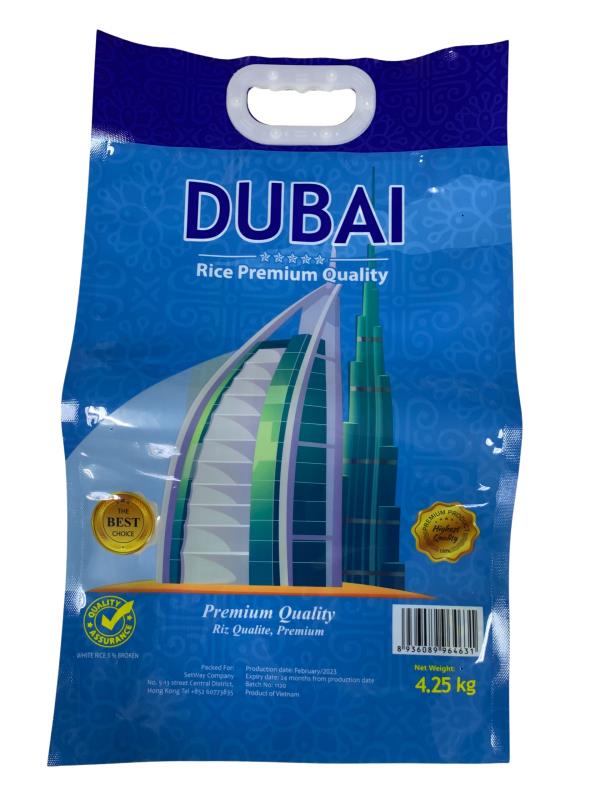

| Function | The coating layer primarily serves to fully cover the bag's surface, with the woven PP fabric coated by a layer of PP adhesive. Coated woven PP bags may not be printed or can only be printed using flexo printing with single-color content, vector images, and relatively sharp details. Please refer to flexo printing technology for further information. | OPP film is a premium-grade film used for gravure printing. Therefore, laminated woven PP bags will surely have prints, and the print content will be printed using gravure printing with true, detailed, sharp images. Please refer to gravure printing technology for further information. |

| Identification | Coated woven PP bags can be coated on the inside or outside of the bag. In the case of the coating layer being on the outside, the bag will have a certain level of gloss or matte finish (depending on the type of coating adhesive). | Laminated woven PP bags always have the OPP film layer on the outside. The bags will have a higher gloss or matte finish and a higher aesthetic value compared to coated woven PP bags. |

| Production Process | Woven PP fabric is coated with an adhesive layer to create coated woven PP bags, then directly printed using flexo printing. Therefore, the production time for coated woven PP bags will be faster than that for laminated woven PP bags. | For laminated woven PP bags, the OPP film will be gravure printed before being laminated onto the bag. Therefore, the production time for laminated woven PP bags will be longer than that for coated woven PP bags. |

| Quantity | Coated woven PP bags are more flexible in terms of quantity. | With gravure printing technology, the entire roll of OPP film needs to be printed, so laminated woven PP bags will need to be produced in a certain quantity depending on the bag size and OPP film roll. |

| Cost | Coated woven PP bags will have a much lower price compared to laminated woven PP bags. | Laminated woven PP bags will have a much higher price compared to coated woven PP bags due to the high cost of OPP film and the higher production cost of gravure printing technology. However, they also provide a higher-quality packaging solution. |

Based on the analysis above, if you need a packaging solution that provides good product containment, effective water resistance and moisture resistance, simple printing with cost-saving options, you can simply order coated woven PP bags with flexo printing. Additionally, laminated woven PP bags will help you achieve a safe, attractive, and competitively priced packaging solution compared to similar products in the market.

Contact Information

Tâm Dương Packaging Company

Hotline: 0928 779 113 (Mr. Đăng) / 0355 508 586 (Mr. Hùng)

Email: marketing@tamduongpack.vn

- Robusta Coffee Export Price Hits 30-Year High

- Robusta prices reach a 16-year high, domestic coffee also surges

- Three issues need to be emphasized when exporting agricultural products to the EU.

- HSBC: Identifying Vietnam's "bottleneck" in attracting FDI

- Agricultural Packaging Tâm Dương - Affirming Brand Value for Your Business

- Export of agricultural products in 2024: Expectation of breakthrough