VICIN CUSTOMERS: MODERN SQUARE BOTTOM BOPP SAG LINE – HIGH AESTHETIC AND TECHNICAL REQUIREMENTS

Vicin needs a line of bags with modern designs, demonstrating brand reputation

With more than 10 years of experience in the field of manufacturing tiling glue, jointing glue, self-leveling mortar, construction chemicals, waterproofing agents, and industrial detergents, Vicin is a reputable enterprise in the construction and manufacturing industries. produces many popular lines of construction materials on the market such as tiling glue products.

Similar to its large and demanding customers, Vicin also requires very high packaging standards and chooses packaging manufacturers very carefully, not only in packaging appearance or tear-resistant packaging quality. impact, but also in the entire professional production process, always committed to zero risk for customers. Only sturdy and modern packaging can serve projects that require sustainability and class.

With many advantages in adhesion and convenience during construction, tile adhesive is increasingly popular. To attract users and develop the market better, large businesses like Vicin not only focus on packaging quality but also optimize packaging costs with beautiful designs as effective brand communication channels. and save.

Requirements to ensure aesthetic and technical features

The Welmax tile and stone adhesive line that Vicin uses Anh Sang as packaging is a key product, contributing to building Vicin's reputation for many years, so it needs a modern design that reflects the brand's reputation. and support for automated packaging technology.

In the context of the market for tiling glue and tile adhesive bags becoming increasingly rich and diverse, Vicin requires packaging that must not only ensure aesthetics, meet marketing and sales needs, but also ensure technicality. art. In particular, this line of tile adhesives has the properties of increased adhesion, flexibility, and very high anti-slip properties, so it needs to be stored in high-quality multi-layer packaging. Specifically:

Sealed packaging keeps the product unaffected by the outside environment

Good moisture resistance and waterproofing

Meets the best physical and mechanical durability, impact resistance, and tear resistance criteria to preserve products in the transportation and high impact conditions of the construction industry.

Eye-catching, creative design, modern printing technology, expressing the customer's brand identity

Exclusive, modern packaging production technology to avoid counterfeiting.

The production process uses automatic packaging technology, requiring the packaging to have a suitable design and structure, optimal for automatic packaging technology.

Large quantity production, fast delivery on schedule as requested by Vicin.

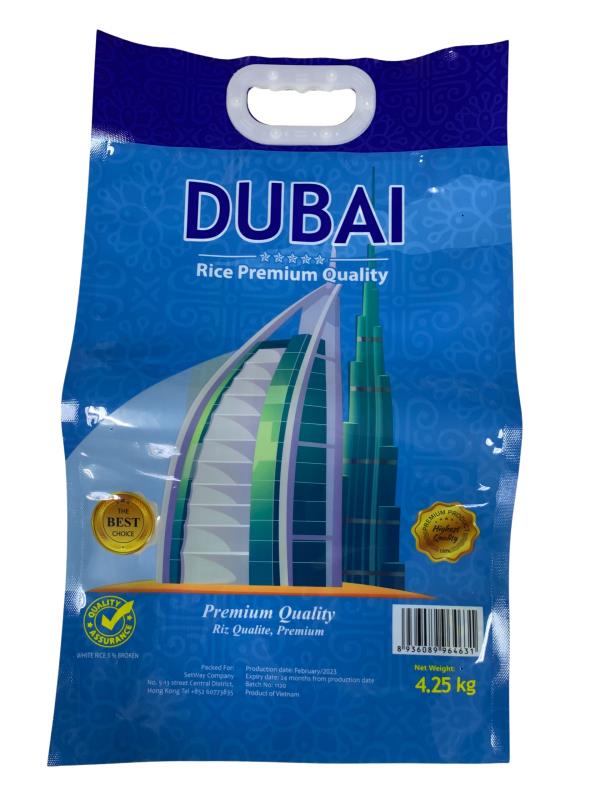

Modern multi-layer square bottom BOPP bags, showing product attributes of the construction industry

To meet Vicin's criteria, Light Packaging proposes a plan that harmonizes modern aesthetic requirements and high technical requirements. That is, using the square bottom BOPP packaging line exclusively designed and manufactured by Light Packaging.

Bottom-sealed BOPP bags containing tile adhesive for Vicin have a multi-layer material structure:

Dimensions: 370 x 470 x110mm (110 is the 2-head valve part) (±5 mm)

Structure: Glossy OPP with gravure printing, coated with white woven PP, Japanese yellow Kraft paper tube inside.

Super smooth air release tattoo with a small line on the upper surface of the capsule.

Fold the valve and automatically glue the bottom of both ends, the valve mouth opens (valve length 5cm - does not exceed the edge of the bag).

After being put into test packaging, the new packaging was used by Vicin and consumers received and positively evaluated the quality, design, and packaging design.